Source: Big Semiconductor Industry Network

On January 28, Fanlin Group released the latest dielectric etching technology Vantex? designed for its most intelligent etching platform Sense.i?. Based on the leading position of Panlin Group in the etching field, this pioneering design will provide higher performance and greater scalability for current and next-generation NAND and DRAM storage devices.

3D storage devices are commonly used in, for example, smart phones, graphics cards, and solid-state storage drives. Chip manufacturers have been continuously reducing the bit cost of advanced technology products by increasing the device size vertically and reducing the critical size (CD) horizontally, increasing the etching aspect ratio in 3D NAND and DRAM to a higher level.

Vantex's new chamber design can etch higher aspect ratio devices with higher radio frequency (RF) power, increasing productivity and reducing costs. The combination of higher power and radio frequency pulse technology can achieve stringent CD control, thereby improving device functions.

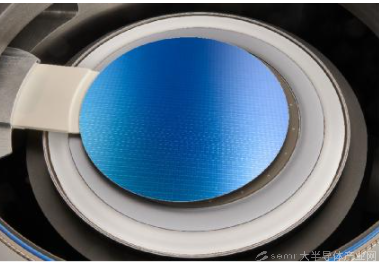

According to the technology roadmap of 3D NAND devices, each generation of etching needs to achieve a greater depth, which also promotes the need to improve the uniformity of the etching profile. Vantex technology controls the vertical angle of etching to meet the design density requirements of these 3D device structures and achieve high yield on the entire 300mm wafer.

"For more than 10 years, Fanlin Group has been leading the industry in the field of high aspect ratio etching. Our unique experience has enabled Vantex's chamber design to provide scalability and innovation for many future technology nodes from the very beginning. "Vahid Vahedi, Senior Vice President and General Manager of Etching Products Division of Fanlin Group, said, "Vantex has redefined the industry benchmark for etching platform performance and production efficiency. This breakthrough etching technology is very useful for customers. Attractive."

Panlin Group's Sense.i etching platform has the Equipment Intelligence® function, which can collect data from hundreds of sensors to monitor system and process performance. With the high-bandwidth communication of the Sense.i system, the Vantex etch chamber collects more data in each wafer than any other equipment on the market-it can analyze and utilize the data more effectively to improve the on-wafer and wafer Performance between circles.

Fanlin Group will continue to provide Vantex on the Sense.i platform to leading customers in the memory industry in order to obtain customer recognition and repeat orders, and help customers achieve high-volume production in 2021.